-

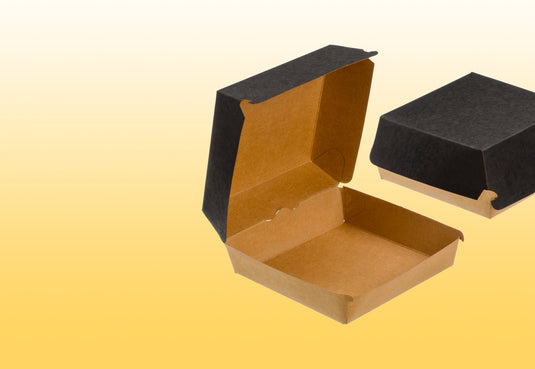

Widely Recyclable

Widely Recyclable

-

Leakproof Lining

Leakproof Lining

-

Hot and Cold Foods

Hot and Cold Foods

-

Freezer Safe

Freezer Safe

Sabert BePulp Rectangular Container Lid Range - Dual Material Options

Food service operations utilizing Sabert BePulp rectangular containers require lid solutions balancing performance requirements with sustainability objectives and operational workflows. The BePulp lid range delivers two material options - premium PP and compostable fibre pulp - both featuring industry-leading clip-seal leak protection for takeaway and delivery applications.

Lid Material Specifications

- PP (Polypropylene) Lid Option:

- Premium plastic construction with complete heat resistance, microwave-safe for full meal reheating, hot cabinet compatible, suitable for hot and cold food applications

- Fibre Pulp Lid Option:

- Natural fibre pulp construction with compostable properties, suitable for hot and cold foods, enhanced sustainability credentials versus plastic alternatives

- Leak Protection System:

- Unique clip-seal mechanism across both lid types delivering industry-leading leak resistance for takeaway and delivery service

- Case Configuration:

- PP lids supplied in 150-unit cases (2 x 75), Pulp lids supplied in 300-unit cases (4 x 75)

- Container Compatibility:

- Designed for Sabert BePulp rectangular container range with fitment verification available through compatibility widget

Material Selection Advantages

- Dual Material Choice - PP and pulp options enable operational requirements alignment balancing performance priorities with sustainability objectives

- Industry-Leading Leak Protection - Unique clip-seal system across both materials provides superior sealing performance for sauced foods and delivery applications

- PP Performance Benefits - Complete heat resistance enables hot cabinet storage and microwave reheating supporting comprehensive foodservice workflows

- Pulp Sustainability Credentials - Natural fibre pulp composition with compostable properties delivers enhanced environmental positioning versus plastic alternatives

- Temperature Versatility - Both lid materials suitable for hot and cold food applications providing operational flexibility

- Delivery Confidence - Robust clip-seal design ensures secure closure during online delivery partner transport and handling

- Material Trade-offs - PP delivers maximum robustness and heat functionality; Pulp provides superior sustainability with appropriate structural performance for compatible applications

Material Selection Guidance

PP Lids - Maximum Performance: Select PP lids when operations require microwave reheating capability, hot cabinet storage, or maximum structural robustness for demanding delivery conditions. Heat-resistant properties enable complete meal reheating and hot holding applications.

Pulp Lids - Enhanced Sustainability: Select pulp lids when prioritizing compostable credentials and natural material positioning. Suitable for hot and cold foods with appropriate structural performance, though not matching PP robustness. Consider specific use case requirements when selecting pulp option.

Target Applications

BePulp Container Operations: Food service businesses, catering operations, takeaway services, and delivery operations utilizing Sabert BePulp rectangular containers requiring lid solutions balancing leak protection, thermal performance, and sustainability objectives across diverse hot and cold food applications.

Operational Flexibility: Dual material options enable strategic lid selection matching operational priorities. PP delivers comprehensive heat functionality and maximum robustness for demanding workflows whilst pulp provides compostable credentials for sustainability-focused positioning. Industry-leading clip-seal system ensures leak protection across both materials supporting confident takeaway and delivery service.

Please Note:

> Use compatibility widget to verify correct lid fitment for specific container sizes.

> PP lids microwave-safe and hot cabinet compatible - supplied in 150-unit cases (2 x 75).

> Pulp lids compostable with natural fibre construction - supplied in 300-unit cases (4 x 75).

> Pulp lids not as robust as PP lids - consider specific use case requirements when selecting material option.

Sabert BePulp Rectangular Container Lid Range - Dual Material Options

Food service operations utilizing Sabert BePulp rectangular containers require lid solutions balancing performance requirements with sustainability objectives and operational workflows. The BePulp lid range delivers two material options - premium PP and compostable fibre pulp - both featuring industry-leading clip-seal leak protection for takeaway and delivery applications.

Lid Material Specifications

- PP (Polypropylene) Lid Option:

- Premium plastic construction with complete heat resistance, microwave-safe for full meal reheating, hot cabinet compatible, suitable for hot and cold food applications

- Fibre Pulp Lid Option:

- Natural fibre pulp construction with compostable properties, suitable for hot and cold foods, enhanced sustainability credentials versus plastic alternatives

- Leak Protection System:

- Unique clip-seal mechanism across both lid types delivering industry-leading leak resistance for takeaway and delivery service

- Case Configuration:

- PP lids supplied in 150-unit cases (2 x 75), Pulp lids supplied in 300-unit cases (4 x 75)

- Container Compatibility:

- Designed for Sabert BePulp rectangular container range with fitment verification available through compatibility widget

Material Selection Advantages

- Dual Material Choice - PP and pulp options enable operational requirements alignment balancing performance priorities with sustainability objectives

- Industry-Leading Leak Protection - Unique clip-seal system across both materials provides superior sealing performance for sauced foods and delivery applications

- PP Performance Benefits - Complete heat resistance enables hot cabinet storage and microwave reheating supporting comprehensive foodservice workflows

- Pulp Sustainability Credentials - Natural fibre pulp composition with compostable properties delivers enhanced environmental positioning versus plastic alternatives

- Temperature Versatility - Both lid materials suitable for hot and cold food applications providing operational flexibility

- Delivery Confidence - Robust clip-seal design ensures secure closure during online delivery partner transport and handling

- Material Trade-offs - PP delivers maximum robustness and heat functionality; Pulp provides superior sustainability with appropriate structural performance for compatible applications

Material Selection Guidance

PP Lids - Maximum Performance: Select PP lids when operations require microwave reheating capability, hot cabinet storage, or maximum structural robustness for demanding delivery conditions. Heat-resistant properties enable complete meal reheating and hot holding applications.

Pulp Lids - Enhanced Sustainability: Select pulp lids when prioritizing compostable credentials and natural material positioning. Suitable for hot and cold foods with appropriate structural performance, though not matching PP robustness. Consider specific use case requirements when selecting pulp option.

Target Applications

BePulp Container Operations: Food service businesses, catering operations, takeaway services, and delivery operations utilizing Sabert BePulp rectangular containers requiring lid solutions balancing leak protection, thermal performance, and sustainability objectives across diverse hot and cold food applications.

Operational Flexibility: Dual material options enable strategic lid selection matching operational priorities. PP delivers comprehensive heat functionality and maximum robustness for demanding workflows whilst pulp provides compostable credentials for sustainability-focused positioning. Industry-leading clip-seal system ensures leak protection across both materials supporting confident takeaway and delivery service.

Please Note:

> Use compatibility widget to verify correct lid fitment for specific container sizes.

> PP lids microwave-safe and hot cabinet compatible - supplied in 150-unit cases (2 x 75).

> Pulp lids compostable with natural fibre construction - supplied in 300-unit cases (4 x 75).

> Pulp lids not as robust as PP lids - consider specific use case requirements when selecting material option.

SKU |

Material |

Case Pack |

Ideal Fill |

Brim Full |

Length |

Width |

Height |

Diameter |

Weight |

Colour |

|---|---|---|---|---|---|---|---|---|---|---|

| PUL51601PP |

PP Plastic |

150 | 229 mm | 165 mm | 7 mm | Clear | ||||

| PUL51602PP |

PP Plastic |

150 | 229 mm | 165 mm | 7 mm | Clear | ||||

| PUL51601PUL |

Pulp |

300 | 229 mm | 165 mm | 7 mm | Natural |