-

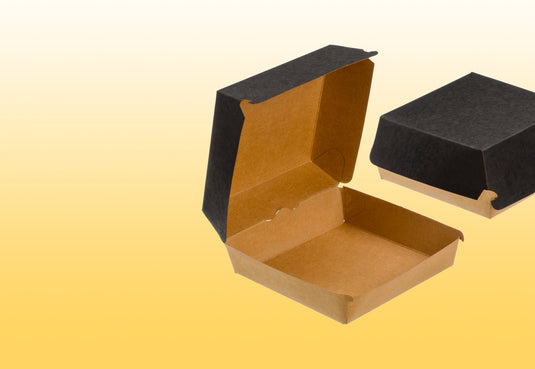

Widely Recyclable

Widely Recyclable

-

Leakproof Lining

Leakproof Lining

-

Cold Foods, Only

Cold Foods, Only

-

Freezer Safe

Freezer Safe

-

Made from Recycled Materials

Made from Recycled Materials

Sabert BePulp Square Bowl Lids - PP and rPET Material Options

For operations utilising Sabert's BePulp square bowl range, these engineered lids deliver proprietary clip-system sealing with material choice matched to service requirements. Available in polypropylene for full heat resistance including microwave and hot cabinet applications, or recycled PET for cold service with enhanced clarity and mainstream recyclability, the lids provide industry-leading leak protection that enables confident takeout service and third-party delivery partnership without spillage incidents compromising brand reputation.

Product Specifications

- Compatibility:

- Designed for Sabert BePulp square bowl range. Reference compatibility widget to confirm correct lid-to-bowl fitment across specific bowl configurations.

- Sealing Technology:

- Sabert's proprietary clip system engineered to deliver market-leading leak protection, securing contents during transportation and preventing spillage in delivery bag environments and customer handling scenarios. The mechanism addresses food delivery's primary packaging failure point through purpose-designed sealing engineering.

- Material Options:

-

Polypropylene (PP) Lids:

- Fully heat resistant for hot food preparations

- Suitable for hot cabinet storage maintaining food at service temperature

- Microwaveable with complete meal enabling customer reheating in original packaging

- Suitable for both hot and cold food applications

Recycled PET (rPET) Lids:

- Suitable for cold or warm products (not direct heat exposure)

- Manufactured from post-consumer recycled PET supporting circular economy principles

- PET Recycle Code No.1 ♳ ensuring mainstream UK kerbside recyclability providing superior end-of-life options

- Enhanced clarity compared to PP delivering improved product visibility for presentation-focused applications

Performance Advantages

- Market-Leading Leak Protection - Proprietary Sabert clip system prevents liquid migration and spillage during delivery transit, protecting brand reputation on third-party platforms where packaging failure generates negative reviews and customer complaints.

- Service-Specific Material Selection - PP option addresses hot food operations requiring microwave capability and hot cabinet storage, whilst rPET serves cold presentations prioritising clarity and recycled content credentials.

- Hot Cabinet Compatibility - PP lids withstand commercial hot holding equipment temperatures, enabling advance meal preparation and service window management in catering operations maintaining food at safe service temperatures.

- Customer Reheating Convenience - PP microwave capability eliminates plate-transfer requirements, improving convenience perception and reducing barriers to repeat delivery ordering in competitive home delivery markets.

- Enhanced Product Visibility - rPET superior clarity showcases food quality and portion generosity in grab-and-go refrigerated displays, driving impulse purchasing through visual appeal assessment.

- Mainstream Recycling Accessibility - rPET Recycle Code No.1 ♳ ensures compatibility with standard UK kerbside collection programmes, enabling practical customer recycling participation without specialist facility requirements.

- Delivery Partnership Confidence - Engineered leak protection enables third-party delivery platform partnership without packaging-related reputation risk, supporting revenue growth through online ordering channels.

Target Applications

Ideal Service Environments: Delivery-focused restaurants, ghost kitchens, catering operations, and meal prep businesses using Sabert BePulp square bowls where material choice aligns to service model—PP lids for hot food delivery requiring microwave reheating and hot cabinet holding, rPET lids for cold grab-and-go presentations prioritising product visibility and recycled content environmental messaging.

Material Selection Guidance: Choose PP lids for hot food delivery operations where customer reheating capability drives repeat ordering and hot cabinet storage supports production workflow efficiency. Specify rPET lids for cold meal prep, salad bars, and refrigerated grab-and-go displays where superior clarity enhances visual merchandising and mainstream recyclability supports practical environmental credentials. The material choice reflects operational priorities—thermal performance versus presentation clarity and recyclability accessibility.

Sabert Brand Excellence

Sabert's proprietary clip system represents focused engineering investment in solving the food delivery industry's most common packaging failure—inadequate sealing that creates spillage during transportation. The technology enables confident participation in third-party delivery platforms where packaging performance directly impacts customer reviews, repeat ordering rates, and platform algorithm ranking. The dual material system acknowledges that hot and cold food services have different technical requirements, providing appropriate specification choice rather than compromise solutions attempting universal application.

Sabert BePulp Square Bowl Lids - PP and rPET Material Options

For operations utilising Sabert's BePulp square bowl range, these engineered lids deliver proprietary clip-system sealing with material choice matched to service requirements. Available in polypropylene for full heat resistance including microwave and hot cabinet applications, or recycled PET for cold service with enhanced clarity and mainstream recyclability, the lids provide industry-leading leak protection that enables confident takeout service and third-party delivery partnership without spillage incidents compromising brand reputation.

Product Specifications

- Compatibility:

- Designed for Sabert BePulp square bowl range. Reference compatibility widget to confirm correct lid-to-bowl fitment across specific bowl configurations.

- Sealing Technology:

- Sabert's proprietary clip system engineered to deliver market-leading leak protection, securing contents during transportation and preventing spillage in delivery bag environments and customer handling scenarios. The mechanism addresses food delivery's primary packaging failure point through purpose-designed sealing engineering.

- Material Options:

-

Polypropylene (PP) Lids:

- Fully heat resistant for hot food preparations

- Suitable for hot cabinet storage maintaining food at service temperature

- Microwaveable with complete meal enabling customer reheating in original packaging

- Suitable for both hot and cold food applications

Recycled PET (rPET) Lids:

- Suitable for cold or warm products (not direct heat exposure)

- Manufactured from post-consumer recycled PET supporting circular economy principles

- PET Recycle Code No.1 ♳ ensuring mainstream UK kerbside recyclability providing superior end-of-life options

- Enhanced clarity compared to PP delivering improved product visibility for presentation-focused applications

Performance Advantages

- Market-Leading Leak Protection - Proprietary Sabert clip system prevents liquid migration and spillage during delivery transit, protecting brand reputation on third-party platforms where packaging failure generates negative reviews and customer complaints.

- Service-Specific Material Selection - PP option addresses hot food operations requiring microwave capability and hot cabinet storage, whilst rPET serves cold presentations prioritising clarity and recycled content credentials.

- Hot Cabinet Compatibility - PP lids withstand commercial hot holding equipment temperatures, enabling advance meal preparation and service window management in catering operations maintaining food at safe service temperatures.

- Customer Reheating Convenience - PP microwave capability eliminates plate-transfer requirements, improving convenience perception and reducing barriers to repeat delivery ordering in competitive home delivery markets.

- Enhanced Product Visibility - rPET superior clarity showcases food quality and portion generosity in grab-and-go refrigerated displays, driving impulse purchasing through visual appeal assessment.

- Mainstream Recycling Accessibility - rPET Recycle Code No.1 ♳ ensures compatibility with standard UK kerbside collection programmes, enabling practical customer recycling participation without specialist facility requirements.

- Delivery Partnership Confidence - Engineered leak protection enables third-party delivery platform partnership without packaging-related reputation risk, supporting revenue growth through online ordering channels.

Target Applications

Ideal Service Environments: Delivery-focused restaurants, ghost kitchens, catering operations, and meal prep businesses using Sabert BePulp square bowls where material choice aligns to service model—PP lids for hot food delivery requiring microwave reheating and hot cabinet holding, rPET lids for cold grab-and-go presentations prioritising product visibility and recycled content environmental messaging.

Material Selection Guidance: Choose PP lids for hot food delivery operations where customer reheating capability drives repeat ordering and hot cabinet storage supports production workflow efficiency. Specify rPET lids for cold meal prep, salad bars, and refrigerated grab-and-go displays where superior clarity enhances visual merchandising and mainstream recyclability supports practical environmental credentials. The material choice reflects operational priorities—thermal performance versus presentation clarity and recyclability accessibility.

Sabert Brand Excellence

Sabert's proprietary clip system represents focused engineering investment in solving the food delivery industry's most common packaging failure—inadequate sealing that creates spillage during transportation. The technology enables confident participation in third-party delivery platforms where packaging performance directly impacts customer reviews, repeat ordering rates, and platform algorithm ranking. The dual material system acknowledges that hot and cold food services have different technical requirements, providing appropriate specification choice rather than compromise solutions attempting universal application.

SKU |

Material |

Case Pack |

Ideal Fill |

Brim Full |

Length |

Width |

Height |

Diameter |

Weight |

Colour |

|---|---|---|---|---|---|---|---|---|---|---|

| PUL53501 |

rPET Plastic |

500 | 136 mm | 136 mm | 18 mm | Clear | ||||

| PUL54124 |

rPET Plastic |

300 | 175 mm | 175 mm | 17 mm | Clear | ||||

| PUL54124PP |

PP Plastic |

300 | 175 mm | 175 mm | 21 mm | Clear |