-

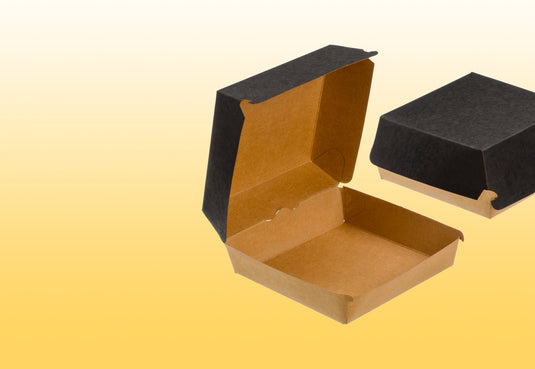

Widely Recyclable

Widely Recyclable

-

Leakproof Lining

Leakproof Lining

-

Hot and Cold Foods

Hot and Cold Foods

-

Freezer Safe

Freezer Safe

-

Reusable

Reusable

Sabert Fastpac Range - Premium Hot Meal Delivery Packaging

For delivery-focused restaurants, meal kit operations, and takeaway services where hot food integrity during transportation determines customer satisfaction, the Sabert Fastpac range delivers engineered performance for demanding delivery conditions. Featuring fully microwaveable construction, vented lid technology, and leak-proof sealing designed to withstand bumpy road transit, this premium polypropylene system maintains food temperature, prevents spillage, and enables direct reheating in original packaging—supporting operational efficiency whilst delivering table-ready presentation quality from kitchen to customer.

Advanced Performance Specifications

- Material Construction:

- Advanced polypropylene (PP) formulation engineered for exceptional thermal performance and structural integrity. Both trays and lids fully microwaveable, enabling customers to reheat meals directly in original packaging without transfer requirements.

- Temperature Capability:

- Performs reliably under commercial heat lamp conditions at temperatures up to 90°C for maximum 4-hour holding periods, supporting kitchen workflow flexibility and service window management. Suitable for refrigerated cold food storage and freezer applications for advance meal preparation operations.

- Leak-Proof Engineering:

- Robust lid-fit mechanism delivers reliable sealing that resists water, heat, grease, and oil migration during transportation. Engineered specifically for delivery service demands where bumpy road conditions challenge conventional container integrity.

- Vented Lid Technology:

- Integrated venting system maintains lid transparency during microwave reheating whilst preventing pressure build-up that causes lid displacement—ensuring safe, controlled reheating without manual intervention or packaging failure.

- Stackability Design:

- Optimised geometry for efficient vertical stacking, maximising cold storage utilisation, simplifying transport organisation, and reducing delivery vehicle cubic capacity requirements for multi-order fulfilment.

- Environmental Credentials:

- Recyclable where facilities exist. Durable construction supports reuse applications for meal prep operations and customers practicing sustainable consumption behaviours.

Operational Advantages

- Delivery-Optimised Durability - Engineered specifically for bumpy road transit conditions, the robust construction and secure lid fit prevent spillage incidents that generate customer complaints, refund requests, and negative reviews in delivery-dependent business models.

- Direct Reheating Convenience - Fully microwaveable tray and lid construction eliminates customer plate-transfer requirements, improving convenience perception and reducing washing-up barriers that influence repeat purchase decisions in home delivery scenarios.

- Vented Microwave Safety - Integrated venting prevents dangerous pressure accumulation and lid ejection during reheating, addressing the primary safety concern customers experience with sealed microwave containers and supporting confident product usage.

- Extended Hold Time Flexibility - Heat lamp tolerance up to 90°C for 4-hour maximum periods enables kitchen production scheduling flexibility during peak demand, supporting advance preparation without compromising food safety or packaging integrity.

- Temperature Maintenance Performance - Superior thermal properties keep food hot during extended delivery journeys, protecting meal quality and temperature safety standards that determine customer satisfaction and repeat business generation.

- Leak-Proof Confidence - Grease, oil, and liquid resistance prevents bag contamination and vehicle mess during transport, reducing driver complaints and protecting ancillary items in multi-order delivery scenarios.

- Space-Efficient Logistics - Stackable design maximises refrigerator utilisation for advance prep operations and delivery vehicle capacity for multi-drop route efficiency, reducing operational costs per delivery.

- Premium Presentation Standards - Table-ready aesthetic quality supports premium pricing strategies and brand differentiation in competitive delivery markets where packaging communicates value proposition before food consumption begins.

Target Applications

Ideal Service Environments: Delivery-focused restaurants, ghost kitchens, meal kit services, corporate catering operations, care home meal delivery programmes, and takeaway establishments where hot food quality during transportation directly impacts business performance. Particularly suited for restaurant-quality main courses, portioned meals, curry dishes, pasta servings, and composed plates requiring secure compartmentalisation and reliable temperature maintenance throughout delivery cycles.

Performance Standards: The Fastpac range addresses the fundamental challenge of hot meal delivery—maintaining food temperature, preventing spillage, and delivering restaurant-quality presentation after transportation through variable conditions. The engineered approach to delivery-specific demands differentiates the range from general-purpose containers that compromise when subjected to real-world transit stresses, supporting operators in delivering the dining experience customers expect even when consuming meals away from the restaurant environment.

Sabert Brand Excellence

Sabert's manufacturing standards deliver rigorous quality control and certified production processes that ensure consistent performance across production batches—critical for operators dependent on packaging reliability to protect brand reputation. The company's focus on food presentation quality recognises that packaging significantly influences perceived value in delivery scenarios where visual first impressions occur before taste evaluation. Sabert's investment in cutting-edge equipment and traceability systems provides the robust, leak-proof product integrity that delivery operations require to maintain customer satisfaction and operational efficiency.

Please Note:

> Microwaveable vented PP lids sold separately—must be ordered as separate line item

> Suitable for heat lamp holding up to 90°C for maximum 4-hour periods—monitor food safety temperatures

> Fully microwaveable construction—customers can reheat meals directly in packaging

> Recyclable where PP recycling facilities exist—availability varies by local authority

> Designed specifically for delivery service demands—engineered for bumpy road conditions

Sabert Fastpac Range - Premium Hot Meal Delivery Packaging

For delivery-focused restaurants, meal kit operations, and takeaway services where hot food integrity during transportation determines customer satisfaction, the Sabert Fastpac range delivers engineered performance for demanding delivery conditions. Featuring fully microwaveable construction, vented lid technology, and leak-proof sealing designed to withstand bumpy road transit, this premium polypropylene system maintains food temperature, prevents spillage, and enables direct reheating in original packaging—supporting operational efficiency whilst delivering table-ready presentation quality from kitchen to customer.

Advanced Performance Specifications

- Material Construction:

- Advanced polypropylene (PP) formulation engineered for exceptional thermal performance and structural integrity. Both trays and lids fully microwaveable, enabling customers to reheat meals directly in original packaging without transfer requirements.

- Temperature Capability:

- Performs reliably under commercial heat lamp conditions at temperatures up to 90°C for maximum 4-hour holding periods, supporting kitchen workflow flexibility and service window management. Suitable for refrigerated cold food storage and freezer applications for advance meal preparation operations.

- Leak-Proof Engineering:

- Robust lid-fit mechanism delivers reliable sealing that resists water, heat, grease, and oil migration during transportation. Engineered specifically for delivery service demands where bumpy road conditions challenge conventional container integrity.

- Vented Lid Technology:

- Integrated venting system maintains lid transparency during microwave reheating whilst preventing pressure build-up that causes lid displacement—ensuring safe, controlled reheating without manual intervention or packaging failure.

- Stackability Design:

- Optimised geometry for efficient vertical stacking, maximising cold storage utilisation, simplifying transport organisation, and reducing delivery vehicle cubic capacity requirements for multi-order fulfilment.

- Environmental Credentials:

- Recyclable where facilities exist. Durable construction supports reuse applications for meal prep operations and customers practicing sustainable consumption behaviours.

Operational Advantages

- Delivery-Optimised Durability - Engineered specifically for bumpy road transit conditions, the robust construction and secure lid fit prevent spillage incidents that generate customer complaints, refund requests, and negative reviews in delivery-dependent business models.

- Direct Reheating Convenience - Fully microwaveable tray and lid construction eliminates customer plate-transfer requirements, improving convenience perception and reducing washing-up barriers that influence repeat purchase decisions in home delivery scenarios.

- Vented Microwave Safety - Integrated venting prevents dangerous pressure accumulation and lid ejection during reheating, addressing the primary safety concern customers experience with sealed microwave containers and supporting confident product usage.

- Extended Hold Time Flexibility - Heat lamp tolerance up to 90°C for 4-hour maximum periods enables kitchen production scheduling flexibility during peak demand, supporting advance preparation without compromising food safety or packaging integrity.

- Temperature Maintenance Performance - Superior thermal properties keep food hot during extended delivery journeys, protecting meal quality and temperature safety standards that determine customer satisfaction and repeat business generation.

- Leak-Proof Confidence - Grease, oil, and liquid resistance prevents bag contamination and vehicle mess during transport, reducing driver complaints and protecting ancillary items in multi-order delivery scenarios.

- Space-Efficient Logistics - Stackable design maximises refrigerator utilisation for advance prep operations and delivery vehicle capacity for multi-drop route efficiency, reducing operational costs per delivery.

- Premium Presentation Standards - Table-ready aesthetic quality supports premium pricing strategies and brand differentiation in competitive delivery markets where packaging communicates value proposition before food consumption begins.

Target Applications

Ideal Service Environments: Delivery-focused restaurants, ghost kitchens, meal kit services, corporate catering operations, care home meal delivery programmes, and takeaway establishments where hot food quality during transportation directly impacts business performance. Particularly suited for restaurant-quality main courses, portioned meals, curry dishes, pasta servings, and composed plates requiring secure compartmentalisation and reliable temperature maintenance throughout delivery cycles.

Performance Standards: The Fastpac range addresses the fundamental challenge of hot meal delivery—maintaining food temperature, preventing spillage, and delivering restaurant-quality presentation after transportation through variable conditions. The engineered approach to delivery-specific demands differentiates the range from general-purpose containers that compromise when subjected to real-world transit stresses, supporting operators in delivering the dining experience customers expect even when consuming meals away from the restaurant environment.

Sabert Brand Excellence

Sabert's manufacturing standards deliver rigorous quality control and certified production processes that ensure consistent performance across production batches—critical for operators dependent on packaging reliability to protect brand reputation. The company's focus on food presentation quality recognises that packaging significantly influences perceived value in delivery scenarios where visual first impressions occur before taste evaluation. Sabert's investment in cutting-edge equipment and traceability systems provides the robust, leak-proof product integrity that delivery operations require to maintain customer satisfaction and operational efficiency.

Please Note:

> Microwaveable vented PP lids sold separately—must be ordered as separate line item

> Suitable for heat lamp holding up to 90°C for maximum 4-hour periods—monitor food safety temperatures

> Fully microwaveable construction—customers can reheat meals directly in packaging

> Recyclable where PP recycling facilities exist—availability varies by local authority

> Designed specifically for delivery service demands—engineered for bumpy road conditions

SKU |

Material |

Case Pack |

Ideal Fill |

Brim Full |

Length |

Width |

Height |

Diameter |

Weight |

Colour |

|---|---|---|---|---|---|---|---|---|---|---|

| HOT76116 |

PP Plastic |

300 | 17 fl oz | 160 mm | 160 mm | 40 mm | Black | |||

| HOT76124 |

PP Plastic |

300 | 25.5 fl oz | 160 mm | 160 mm | 60 mm | Black |